Facility

Technique

Along with the demand for stainless steel pipes, we have been constantly updating our technology through research and development. We are committed to pursuing reliable and good products, and will introduce our state-of-the-art facilities that incorporate computers to support our know-how and the facilities that support our workplaces.

We are mainly engaged in the pipe making process and polishing process for ICS pipes, as well as the chamfering process and packaging process for both ICS and stainless steel pipes.

We mainly process both ICS and stainless steel pipes.

We are making the steel pipe that will serve as the base for the ICS pipe.

We carry out pipe making process, polishing process, straightening, and inspection of stainless steel pipes.

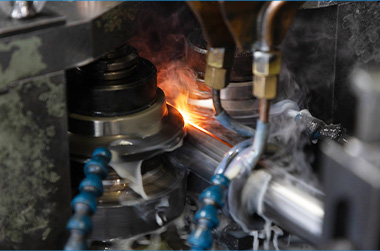

This is a welding method in which welding material is sandwiched between disc electrodes and energized while the disc electrodes rotate to continuously join welding material by heating through electrical resistance.

This method generates an arc between the material to be welded and a tungsten electrode to melt and weld the material.

Welding is performed by passing a pipe through an induction coil and applying an induction current to the pipe through the inductive action of the high-frequency current passed through the coil to heat and pressure weld the joint.

| main machine | ability | number of large objects such as cars, computers, etc. | |

|---|---|---|---|

| High-frequency tube making machine | φ13~φ38 | 1 | |

| Clad Pipe Forming Machine | φ9.5~φ38 | 3 | |

| Stainless Steel Pipe Forming Machine | φ6~φ38 | 9 | |

| Pipe Polishing Machine | φ6~φ38 | 10 | |

| Barrel Finishing Machine | 1 | ||

| Pipe cutting machine | Roll cut and bite cut | 10 | |

| Pipe chamfering machine | NPW2500 etc. | 13 | |

| Pipe Forming Machine | Square pipe, oval pipe | 2 | |

| Pipe straightening machine | 3 | ||

| overhead crane | 11 | ||

| automatic sawing machine | Amada | 2 | |

| Circular sawing machine | Tsune Precision Machinery | 1 | |

| Automatic pipe wrapping machine | 3 | ||

| machining center | 1 | ||

| NC Lathe | 1 | ||

| pipe bender | 2 | ||

| universal testing machine | 10TON | 1 | |

| Micro hardness tester | 1 | ||

| stereo microscope | 1 | ||

| Eddy current flaw detector | 9 | ||

| Rotary Swager | Outer diameter φ33, 3.7kw, 6p | 1 | |

| Coiled tube winders | 1 | ||

| Water pressure tester | 1 | ||

| microscope | 1 | ||

| Contour Measuring Instruments | 1 | ||

| Roundness and cylindrical shape measuring machine | 1 | ||

| Hybrid non-destructive testing machine | 1 | ||

CONTACT

TEL.076-277-1145

Reception hours: Weekdays 8:00-17:00